s550 steel shot steel shot abrasive blasting media

Steel Shot and Grit have appropriate hardness,cleaning quickly and bearing good rebound resilience, the internal corner or complex shape products can evenly and quickly cleaning, shortening the processing time, increase throughput, reduce the production cost.

s550 steel shot steel shot abrasive blasting media Specifications :

| Price | Contact Us |

| Model Number | s550 |

| Place of Origin | Shandong, China |

| Payment Terms | T/T, L/C, Western Union, etc. |

| Delivery Detail | 10-25 Working Days. |

| Keyword | Steel Shot Beads |

s550 steel shot steel shot abrasive blasting media Detail Introduction :

S550 Steel shot and Grits For Wholesale

Model:

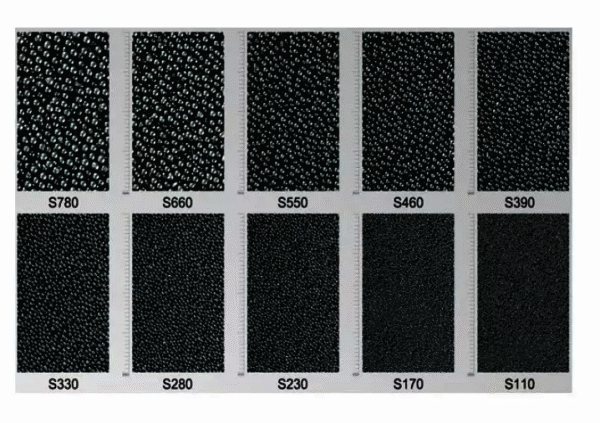

S780/SS2.5,S660/SS2.0 ,S550/SS1.7 ,S460/SS1.4 ,S390/SS1.2 ,S330/SS1.0 ,S280/SS0.8 ,S230/SS0.6 ,S170/SS0.5, S140/SS0.4 ,S110/SS0.3 ,S70/SS0.2

Application

1.Blast cleaning: Used for blast cleaning of casting, die-casting,forging; sand removal of casting, steel plate, H type steel, steel structure.

2..Rust removal: Rust removal of casting, forging, steel plate, H type steel,steel structure.

3.Shot peening: Shot peening of gear, heat treated parts.

4.Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure.

Product | Steel shot , Steel grit , Cut wire shot ,etc |

Size | Steel shot : S70,S110,S130,S170,S230,S280,S330,S390,S460,S550,S660,S780,S930,etc Steel grit : G14,G16,G18,G25,G40,G50,G80,G120,etc Cut wire shot : 0.5mm,1.0mm,1.5mm,2.0mm ,etc |

Standard | EN12413, ISO9001:2008 |

Micro structure | Tempered Martensite or Sorbite |

Hardness | HRC 40-65 |

Field | Cement plant , Mining , Power station , Chemical industries ,etc |

MOQ | 1 ton |

Lead Time | In 15 days for quantity under 100 tons |

Testing | Size testing ,Hardness testing ,Chemical composition testing |

Free Sample | Available upon request |

Our Service:

- Simple installation

- Corrosion proof

- Dimensionally accurate

- Good abrasion – improves work efficiency

- Highly durable – reduces manufacturing time and cost

- Stable peening effect because of uniform hardness and particles

- Heat treated and cold drawn to achieve hardness and homogeneit

- Consistent ing and cleaning

- Lower consumption for economical peening applications

Telephone :+86 157 6285 8378

Telephone :+86 157 6285 8378 WhatsApp :+86 157 6285 8378

WhatsApp :+86 157 6285 8378 Email :

Email :